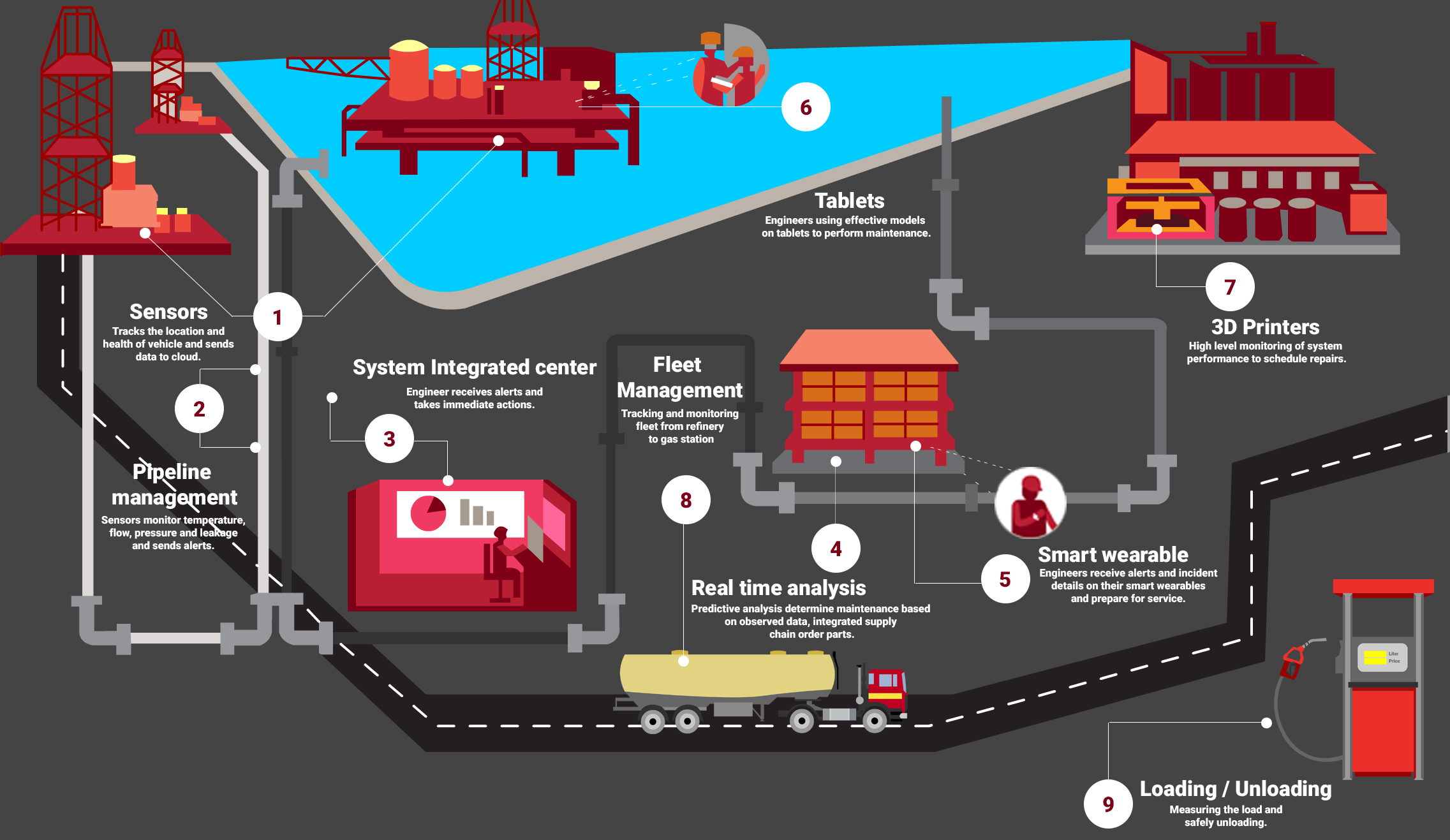

IoT in Oil and Gas: 8 Easy Steps to Monitor Operations

Want to learn more about the incorporation of IoT in the oil an gas industry? Check out this post to learn more about the eight easy steps to monitor operations with IoT.

Join the DZone community and get the full member experience.

Join For Free“The Internet of Things is not a concept; it is a network, the true technology-enabled Network of all networks.” –Edewede Oriwoh

In the development of any industry or technology right from its birth, the initial phase tells about the existence of that technology. And, the same has been the case for the IoT in the oil and gas industry. In the industrial oil and gas industry, the major satisfaction lies not in managing the equipment and devices or customer relationships but rather adding value to these. To find value in oil and gas industry, an integrated system plays a major role. Here are eight steps that tell how Industrial IoT implementation in the oil and gas industry works:

1. Sensors

Tracking the live location of a vehicle was always a key challenge in the oil and gas industry. Sensors read the pertinent data, like flow rate, temperature, pressure, and, then, gateways at the site connect these sensors to wireless networks. Once they get connected to the wireless networks, they connect to smartphones and tablets so that the data can be read and analyzed by the field engineers. From the recent studies, it has been known that 40 percent of all the data by 2020 will come from the connected sensors.

Biz4Intellia, an end-to-end comprehensive Industrial IoT solution has made the best and optimized use of sensors and controllers. These network of devices gather the real-time data to analyze and monitor the present status of the plant. According to few research and reports, it was found that out of all the devices, sensors were the major ones which helped in finding the major problems in valve, pipeline and compressor before the situation become catastrophic.

2. Pipeline Management

As we come from upstream to downstream, a higher network integrity is found. According to the recent research, it was known that an approximate of $10 billion of loss was there due to leakage of fuel, and, thus, it led to the development of the Pipeline management. A midstream company send its data across these pipelines and help the engineers find the optimized route. Biz4Intellia, an end-to-end Industrial IoT solution, brushed the characteristics of oil and gas pipeline management. Factors like downtime got reduced, and regular maintenance got scheduled with the help of the pipeline at the midstream. Aspects like temperature, flow, and pressure are monitored by the sensors and are, then, inspected by end-to-end pipelines.

3. System Integrated Center

This step integrates the IoT platforms with core business processes. The system at midstream is relatively more mature in monitoring the risks and optimizing the operations as the systems are highly automated and process controlled. The system quickly integrates the data received from all other devices and sends alerts for taking immediate actions. It not only does this, but the different organizations are adopting a different system control center, which can capture the data relating to time, temperature, and pressure. Beyond the technical challenges that are faced in the integration of all the devices, developing such a system requires deep insight.

4. Real-Time Analysis

Whenever there is a large amount of complex data, predictive analysis becomes a major concern. Predictive analysis keeps the track of the real-time data and lets you know even about the minute changes in the behavior of the equipment. Whenever a failure occurs, alerts are sent to the engineer and changes are made.

5. Tablets and Smart Wearables

With IoT, the systems are connected to one network and programmed to relay information back to a device, such as a smartphone or a tablet, that is connected to the same network. Through these IoT tools, oil and gas workers can have access to information gathered, which helps them to understand how the system is performing. They can also monitor the systems and analyze key information from any location.

6. 3-D Printers

Advanced products and smooth running of the processes are all possible by the beauty of the 3-D printing in the oil and gas industry. 3-D printing is a industrial IoT solution for oil and gas that has made the representation of the assets more cost-effective and the processes faster. When the data gets scanned from respective devices, then, one can know whether the replacement part can fit the existing part, and the documentation tells us about improving the design of a product and reproducing the tooling components. A concept of reverse engineering is used in the oil and gas industry that measures the shape and size of every tool.

7. Loading and Unloading

The measurement of the load on the truck has been a problem and a critical factor while utilizing the assets in the transportation and logistics business. According to the recent US regulations in fleet management, a cap has been put on the load of the truck so you cannot exceed the limit. And, you would not want to load the truck lesser than the limit, because you don’t want to lose the potential profit. With IoT in the oil and gas industry, you can monitor the real-time loading /unloading with smart truck/trailer weighing solutions.

8. Fleet Management

The off-road sensors and the one fitted inside the fleet helps in tracking the real-time location and health of the vehicle. The advanced and intelligent fleet system has increased the overall efficiency and reduced traffic incidents. Sensors help to monitor the data from multiple locations and track the equipment so that risks can be reduced. With the present technology of IoT in oil and gas, tracking the real-time location and health of the vehicle has become an easy game. As in the present era, everything is independent of the human inputs; the IoT in the oil and gas industry is also independent of the human manpower.

Opinions expressed by DZone contributors are their own.

Comments